#bioplastic utensils

Explore tagged Tumblr posts

Text

How to Integrate Bioplastic Utensils into Your Zero-Waste Lifestyle: Tips for Restaurants

ByHemp Blogger

August 5, 2024

Blog

As more restaurants strive to adopt eco-friendly practices, integrating bioplastic utensils into daily operations is an effective way to minimize environmental impact. Here’s how your restaurant can seamlessly incorporate these sustainable utensils into your zero-waste lifestyle.

Understand the Benefits of Bioplastic Utensils

Bioplastic utensils, made from renewable resources like cornstarch, offer several advantages:

Compostable: Unlike traditional plastic, bioplastics break down naturally, reducing landfill waste.

Eco-friendly Production: They are produced using fewer fossil fuels, which lowers the overall carbon footprint.

Assess Your Current Usage

Start by evaluating your current usage of plastic utensils. Identify areas where bioplastic alternatives can be introduced. Common areas include takeout services, outdoor dining, and catering events.

Educate Your Staff

Ensure that all staff members understand the importance and benefits of switching to bioplastic utensils. Provide training on how to properly dispose of these utensils to ensure they are composted correctly.

Partner with a Reliable Supplier

Find a reliable supplier that offers high-quality bioplastic utensils. GreenTek Planet provides a wide range of compostable products, ensuring your restaurant can maintain its commitment to sustainability without sacrificing quality.

Update Your Customers

Inform your customers about the switch to bioplastic utensils. Use signage, menus, and social media to highlight your commitment to sustainability. This not only educates your customers but also enhances your restaurant’s eco-friendly reputation.

Implement Proper Disposal Systems

Set up clearly labeled compost bins for disposing of bioplastic utensils. Educate customers on how to use these bins correctly to ensure utensils are composted rather than ending up in general waste.

Monitor and Adjust

Regularly review your usage and disposal of bioplastic utensils. Gather feedback from staff and customers to identify any areas for improvement. Adjust your practices as necessary to maximize the benefits of using bioplastic utensils.

Integrating bioplastic utensils into your restaurant’s daily operations is a simple yet impactful way to support a zero-waste lifestyle. By understanding the benefits, educating your staff, partnering with a reliable supplier like GreenTek Planet, and engaging your customers, you can significantly reduce your environmental footprint while maintaining high standards of service.

For more information on bioplastic utensils and other eco-friendly products, visit GreenTek Planet.

#bioplastic utensils#zero-waste lifestyle#sustainable restaurant practices#compostable utensils#eco-friendly dining#GreenTek Planet#renewable resources#reduce landfill waste#environmentally friendly utensils#compostable products for restaurants

0 notes

Text

The global bioplastic utensils market revenue was valued at USD 43.56 billion in 2024. It is estimated to reach USD 69.51 billion by 2033, growing at a CAGR of 5.33% during the forecast period (2025–2033).

#Bioplastic Utensils Market#Bioplastic Utensils Market Size#Bioplastic Utensils Market Share#Bioplastic Utensils Market Trends

0 notes

Text

How Does Sustainable Tableware Compare to Traditional Alternatives

As eco-conscious living gains momentum, many individuals and businesses are rethinking everyday items—including tableware. But how does sustainable tableware truly stack up against traditional alternatives like plastic, ceramic, or glass? In this article, we explore the environmental, economic, and practical aspects of sustainable tableware to help you make informed choices for your home, restaurant, or event.

What Is Sustainable Tableware? Sustainable tableware refers to plates, bowls, cups, and utensils made from renewable, biodegradable, or recyclable materials. These can include bamboo, palm leaf, cornstarch-based bioplastics, wheat bran, and recycled glass. The goal is to reduce environmental impact during production, use, and disposal.

Traditional tableware, on the other hand, typically consists of single-use plastic, ceramics, porcelain, or metal. While these materials serve their purpose, they often come at a high environmental cost due to energy-intensive manufacturing and long decomposition periods.

Environmental Impact 🌿 Sustainable Tableware: Designed with the Planet in Mind A key benefit of sustainable tableware lies in its minimal impact on the environment.

Numerous items are designed to break down naturally, crafted from rapidly renewable materials and intended for composting or biodegradation. For example:

Bamboo utensils can decompose in just a few months.

Made from fallen palm leaves, they require no added chemicals or manufactured bonding agents.

Sugarcane bagasse plates are made from repurposed agricultural byproducts, reducing waste and promoting sustainability.

By choosing eco-friendly alternatives, you reduce landfill waste, conserve resources, and limit pollution.

♻️ Traditional Tableware: Durability with Drawbacks Traditional materials like ceramic and glass are durable and reusable—but require significant energy and raw materials for production. Plastic tableware, while cheap and convenient, often ends up in oceans and landfills, taking hundreds of years to decompose. It also contributes to microplastic pollution, affecting marine life and entering the human food chain.

Cost and Accessibility 💰 Upfront Costs vs. Long-Term Savings Sustainable tableware often comes with a slightly higher upfront cost, especially for premium products like bamboo fiber bowls or biodegradable utensils. Still, the initial expense is often offset by long-term savings and a reduced environmental impact.

For instance:

Businesses using compostable disposables may reduce waste disposal fees.

Home users investing in reusable bamboo plates save money over time by avoiding repeated purchases of single-use products.

🛒 Availability and Consumer Choice Thanks to growing demand, sustainable tableware is more accessible than ever. Many retailers, both online and offline, offer a wide range of options catering to various budgets and needs. From picnic sets to elegant dinnerware, eco-friendly options are no longer limited or niche.

Durability and Performance 🔍 Comparing Strength and Functionality While traditional materials like porcelain or stainless steel are known for their strength, modern sustainable alternatives are surprisingly durable and functional:

Crafted from palm leaves, these plates are durable and resistant to moisture.

Utensils made from cornstarch bioplastics can handle hot foods and drinks without breaking down.

Sustainable bamboo dinnerware offers a perfect balance of lightweight design and everyday strength.

However, some compostable options are best suited for short-term or single-use scenarios, such as parties or events, rather than daily kitchen use.

Aesthetic and Design Variety Sustainable tableware doesn’t just perform well—it often looks great too. With earthy tones, natural textures, and minimalist aesthetics, many eco-friendly products align with modern design trends. Brands now offer customizable options, making them ideal for events, branding, or unique dining experiences.

Traditional tableware still has its place, especially for formal dining or heritage-rich settings. But sustainable alternatives are increasingly seen as stylish, innovative, and socially responsible.

Disposal and End-of-Life Considerations One major differentiator between the two lies in how the products are discarded:

Biodegradable tableware is often suitable for home composting or can be processed in commercial composting centers.

Some biodegradable options break down naturally, returning nutrients to the soil.

In contrast, plastic tableware and even broken ceramics typically end up in landfills due to limited recycling options.

Knowing how to properly dispose of your tableware can dramatically impact your overall carbon footprint.

Conclusion: Is Sustainable Tableware the Better Choice? When comparing sustainable tableware to traditional alternatives, the benefits are clear. Sustainable options offer:

Lower environmental impact

Reasonable long-term cost

Growing availability

Competitive durability

Stylish aesthetics

While traditional tableware still has value in certain contexts, particularly in terms of durability and formal presentation, sustainable tableware is quickly becoming the preferred choice for individuals and businesses looking to align with eco-friendly values.

Making the switch is not just about the planet—it’s also about embracing innovation, reducing waste, and making more responsible decisions in our everyday lives.

Frequently Asked Questions (FAQs)

Is sustainable tableware really biodegradable? Yes, most sustainable tableware is made from plant-based or organic materials that decompose naturally. However, always check the label—some items may require industrial composting.

Can I use sustainable tableware in the microwave or dishwasher? It depends on the material. Many bamboo fiber and palm leaf products are microwave- and dishwasher-safe, while others may warp or degrade with heat. Always refer to manufacturer guidelines.

Are there sustainable alternatives for cutlery too? Absolutely! Eco-friendly cutlery options include bamboo, cornstarch-based bioplastics, and even edible options made from wheat or rice.

Where can I buy sustainable tableware? You can find eco-friendly tableware in most major supermarkets, specialty eco-stores, or online retailers like Amazon, Etsy, and dedicated sustainability brands.

0 notes

Text

Polylactic Acid (PLA) Market Analysis: Key Players and Competitive Landscape

Rising Demand for Biodegradable and Sustainable Materials Fuels Growth in the Polylactic Acid (PLA) Market.

The Polylactic Acid Market Size was valued at USD 1.2 Billion in 2023 and is expected to reach USD 5.2 Billion by 2032, growing at a CAGR of 17.7% over the forecast period 2024-2032.

The Polylactic Acid (PLA) Market is driven by increasing demand for sustainable and biodegradable alternatives to traditional plastics. PLA, derived from renewable sources like corn starch and sugarcane, is widely used in packaging, textiles, agriculture, biomedical applications, and 3D printing. With rising environmental concerns and government regulations promoting bioplastics, the market is expanding as industries transition toward eco-friendly materials.

Key Players

NatureWorks (Ingeo biopolymer, Ingeo PLA)

Cargill (NatureWorks Ingeo, Cargill PLA)

TotalEnergies Corbion (Luminy PLA, Luminy Biopolymer)

BASF (Ecoflex, Ecovio)

Novamont (Mater-Bi, Mater-Bioplastics)

Futerro (Futerro PLA, Futerro Bio-Polymer)

Braskem (I’m green, I’m green Bio Plastic)

PLA Plant (PLA Resins, PLA 4042D)

SK Chemicals (Skygreen PLA, Ecoflex PLA)

Hisun Biomaterials (HISUN PLA, HISUN Bio-PLA)

Future Scope

The PLA market is expected to witness substantial growth as industries shift towards circular economy practices and biodegradable alternatives. The packaging sector remains the largest consumer of PLA due to its compostability and lower carbon footprint compared to conventional plastics. The medical industry is also seeing increased adoption of PLA in biodegradable sutures, tissue engineering, and drug delivery systems. Additionally, the growing popularity of 3D printing and innovations in high-performance PLA blends are expanding market potential. As more governments ban single-use plastics, PLA is emerging as a preferred solution for sustainable product development.

Emerging Trends

The market is shifting toward high-heat-resistant PLA, making it suitable for hot beverage cups, automotive parts, and durable goods. Blended PLA composites with cellulose, hemp, and other bio-based fibers are gaining traction for enhanced mechanical strength and sustainability. The food & beverage industry is increasingly adopting PLA-based biodegradable food containers, utensils, and films, reducing reliance on petroleum-based plastics. Furthermore, advancements in PLA recycling technologies and the development of marine-degradable PLA variants are paving the way for more sustainable applications.

Key Points

Rising demand for biodegradable plastics in packaging, medical, and 3D printing industries.

Government policies supporting bioplastics and bans on single-use plastics driving growth.

Innovations in high-heat-resistant and reinforced PLA materials for industrial applications.

Increased adoption in medical and healthcare industries for biodegradable implants.

Advancements in PLA recycling and marine-degradable PLA for sustainability.

Conclusion

The Polylactic Acid (PLA) Market is set for strong expansion as industries embrace sustainable solutions and regulatory support increases. With ongoing research and technological advancements, PLA is becoming a key material in the transition to a low-carbon, circular economy. As industries and consumers prioritize eco-friendly alternatives, PLA will continue to play a crucial role in reducing plastic waste and promoting sustainable development worldwide.

Read Full Report: https://www.snsinsider.com/reports/polylactic-acid-pla-market-1808

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Polylactic Acid (PLA) Market#Polylactic Acid (PLA) Market Size#Polylactic Acid (PLA) Market Share#Polylactic Acid (PLA) Market Report#Polylactic Acid (PLA) Market Forecast

0 notes

Text

Eco-Friendly Food Packaging Material: A Sustainable Solution

The increasing awareness of environmental conservation has caused a significant shift in how businesses and consumers approach packaging. Traditional materials such as plastic, although convenient, contribute significantly to environmental pollution. Consequently, the demand for eco friendly food packaging material has increased, providing an alternative that is both functional and friendly to the planet.

What is Eco-Friendly Food Packaging Material? Eco-friendly food packaging material refers to packaging solutions that reduce environmental impact throughout their lifecycle. These materials are biodegradable, recyclable, or compostable and often made from renewable resources. They aim to reduce waste, conserve natural resources, and lower carbon footprints without compromising the safety and freshness of food products.

Common Types of Eco-Friendly Food Packaging Material Biodegradable Packaging Composed from organic elements like cornstarch, sugarcane, or seaweed, biodegradable packaging material decomposes fast and in an environmentally friendly manner. They are perfect for disposable containers, straws, and utensils.

Compostable Packaging Compostable products degrade to nutrient-rich compost through controlled conditions. Packaging materials from bamboo, palm leaves, or PLA, which is a type of plastic manufactured from corn starch, fall under this category.

Recycled Paper and Cardboard Recycled paper is very popular for food boxes, wraps, and bags. They are light in weight and inexpensive, saving forests by decreasing the demand for virgin paper production.

Edible Packaging Edible packaging is the latest innovation that comes from materials such as rice, potatoes, or gelatin. These do not create any waste but also add value to the culinary experience.

Glass Containers Though not new, glass is a reusable and 100% recyclable option. It's commonly used for jars, bottles, and storage containers in the food industry.

Plant-Based Plastics Also known as bioplastics, these are made from plant sources like sugarcane or cassava. They mimic the durability of traditional plastics but degrade much faster.

Advantages of Using Eco-Friendly Food Packaging Material Environmental Protection These materials reduce waste and pollution, helping to combat issues like ocean plastic accumulation and land degradation.

Conservation of Resources Using renewable or recycled materials conserves non-renewable resources like petroleum, which is heavily relied upon in conventional plastic production.

Health Benefits Eco-friendly materials are often free from harmful chemicals like BPA, ensuring safer food storage and consumption.

Corporate Responsibility Adopting sustainable practices enhances a company’s image and demonstrates its commitment to environmental stewardship.

Challenges in Transitioning to Eco-Friendly Food Packaging There are challenges for the widespread adoption of eco-friendly food packaging material, though the benefits of such material are obvious: Cost: Eco-friendly materials are normally more expensive than traditional plastics. Limited Availability: Eco-friendly alternatives may not be accessible in all areas. Durability Issues: Some biodegradable packaging materials do not have the same strength and water resistance as traditional food packaging. The Future of Food Packaging With technological advancement, the production of environmentally friendly food-packaging material is becoming cheaper and more efficient. Also, innovations like smart packaging, monitoring food freshness while being environmentally sound, are on the rise. Further driving is being gained with the stricter regulations from governments and organizations on the single-use plastics.

Conclusion

Eco-friendly food packaging material is more than a trend; it's a necessity for a sustainable future. We can reduce environmental harm, support global efforts to mitigate climate change, and provide a healthier planet for future generations through embracing these materials. This is a small step for either a business or a consumer, but with significant impacts.

1 note

·

View note

Text

Cutlery for Restaurants: Trends and Innovations to Watch

In the ever-evolving world of restaurant design and dining experiences, cutlery plays a critical role that extends beyond its functional purpose. It contributes significantly to the aesthetic and thematic elements of the dining experience, influencing both the ambiance and the impression of the restaurant. As dining preferences shift and the culinary landscape evolves, cutlery trends and innovations are also advancing, reflecting changes in style, material, and functionality. Here’s a comprehensive look at the latest trends and innovations in cutlery for restaurants.

#### 1. **Sustainable Materials**

One of the most notable trends in cutlery is the shift toward sustainable materials. With growing environmental concerns, restaurants are increasingly opting for cutlery made from eco-friendly materials. Bamboo, recycled stainless steel, and biodegradable plastics are becoming popular choices. These materials not only reduce the environmental impact but also align with the values of eco-conscious diners. Brands are developing innovative materials, such as cutlery made from reclaimed ocean plastics or plant-based bioplastics, reflecting a commitment to sustainability.

#### 2. **Minimalist Designs**

Minimalist design is making a strong statement in modern cutlery. Sleek, simple lines with understated elegance are trending, moving away from ornate and heavy designs. This trend reflects a broader movement towards simplicity and functionality in dining. Minimalist cutlery often features smooth, clean surfaces and ergonomic shapes that enhance the dining experience without overwhelming the table setting. This design philosophy is popular among fine dining establishments and modern bistros alike.

#### 3. **Mixed Materials**

Combining different materials in cutlery is gaining traction as designers explore new ways to create visually striking and functional pieces. For example, cutlery sets that mix stainless steel with wooden or ceramic handles offer a unique aesthetic appeal. This trend allows for greater customization and can complement various dining themes, from rustic to contemporary. The blend of materials not only enhances visual interest but also provides functional benefits, such as improved grip and durability.

#### 4. **Color and Finish Innovations**

The traditional silver or stainless steel cutlery is now being complemented by a range of color and finish options. Blackened stainless steel, matte gold, and rose gold finishes are popular choices that add a touch of luxury and sophistication. These finishes can be used to match or contrast with the restaurant’s decor, creating a cohesive and stylish dining environment. Additionally, color-coated cutlery offers a playful and modern twist, allowing restaurants to express their unique brand identity.

#### 5. **Ergonomic and Functional Designs**

As dining experiences become more sophisticated, the focus on ergonomic and functional cutlery designs is increasing. Ergonomic handles that provide comfort during use are becoming standard, especially in high-end dining establishments where attention to detail is crucial. Innovations in design also include utensils with specialized functions, such as multi-purpose knives that combine serrated edges with straight blades or spoons designed with built-in measuring tools.

#### 6. **Customizable and Personalized Cutlery**

Personalization is a growing trend in cutlery, allowing restaurants to customize pieces with their logo or specific design elements. This trend is particularly popular for high-end establishments and special events, where unique cutlery can enhance the dining experience and serve as a memorable keepsake. Customizable cutlery can also reflect the restaurant’s branding and create a distinctive identity.

#### 7. **Smart Cutlery**

The concept of smart cutlery is on the horizon, integrating technology with traditional dining tools. Although still in its early stages, innovations include cutlery that tracks dietary intake or monitors food temperature. These smart features are designed to enhance the dining experience and provide additional value to diners. While more common in tech-forward restaurants and experimental dining spaces, this trend indicates a growing interest in merging technology with everyday dining.

#### 8. **Durability and Maintenance**

As restaurants prioritize cost-efficiency and longevity, cutlery durability is a key consideration. Innovations in material science are leading to the development of more resilient cutlery that can withstand frequent use and rigorous cleaning processes. High-quality stainless steel and titanium coatings are examples of materials that offer enhanced durability while maintaining aesthetic appeal. Additionally, easy-to-clean designs and finishes that resist stains and corrosion contribute to lower maintenance costs and longer-lasting cutlery.

#### 9. **Cultural Influences**

Cultural influences are also shaping cutlery trends. Restaurants offering international cuisines are incorporating cutlery designs that reflect the traditional eating utensils of various cultures. For example, Japanese-inspired chopsticks, Indian-style thalis, or Moroccan tagines are influencing the design and presentation of cutlery. This trend allows restaurants to provide an authentic dining experience while celebrating global culinary traditions.

#### 10. **Vintage and Retro Revival**

Vintage and retro styles are making a comeback in cutlery design, reflecting a nostalgia for classic dining aesthetics. Cutlery sets with intricate patterns, ornate handles, and traditional shapes are popular in establishments aiming to evoke a sense of history and elegance. This trend appeals to diners seeking a touch of old-world charm in their modern dining experiences.

#### Conclusion

The evolution of cutlery in restaurants reflects broader trends in design, sustainability, and technology. From sustainable materials and minimalist designs to customizable and smart cutlery, innovations are continually reshaping how restaurants approach their dining experiences. As the industry moves forward, staying abreast of these trends will allow restaurateurs to enhance their service, reflect their brand identity, and meet the evolving expectations of their diners. Whether focusing on elegance, functionality, or sustainability, the right cutlery can elevate the dining experience and contribute to the overall success of a restaurant.

0 notes

Text

Consumer Trends: Growing Demand for Biodegradable Tableware in Everyday Use

Introduction

In recent years, there has been a noticeable shift in consumer preferences towards more sustainable and eco-friendly products, and biodegradable tableware is no exception. As people become increasingly aware of environmental issues such as plastic pollution and the impact of non-biodegradable materials on ecosystems, there has been a surge in demand for biodegradable alternatives, especially in everyday use items like tableware.

Rising Environmental Awareness

One of the key drivers behind the growing demand for biodegradable tableware is heightened environmental consciousness among consumers. Individuals and households are actively seeking ways to reduce their carbon footprint and minimize plastic waste. Biodegradable tableware, which is made from renewable resources such as plant fibers, sugarcane bagasse, or even bioplastics derived from corn starch, offers a sustainable solution compared to traditional plastic or styrofoam options.

Preference for Sustainable Products

Consumers are increasingly making purchasing decisions based on sustainability criteria. They prefer products that are not only functional and aesthetically pleasing but also align with their values of environmental stewardship. Biodegradable tableware meets these criteria by providing a viable alternative that reduces reliance on non-renewable resources and minimizes waste generation.

Regulatory Support and Certification

The support of regulatory bodies and certifications also plays a crucial role in driving consumer confidence in biodegradable tableware. Certifications such as compostability certifications (e.g., ASTM D6400, EN 13432) assure consumers that the products meet certain environmental standards and will break down safely and efficiently in composting facilities. This assurance further enhances the appeal of biodegradable tableware among environmentally-conscious consumers.

Advancements in Technology and Design

Another factor contributing to the rising demand for biodegradable tableware is the continuous innovation in manufacturing processes and product design. Manufacturers are constantly improving the durability, heat resistance, and aesthetic appeal of biodegradable materials, making them more suitable for various applications beyond just disposable utensils and plates. This expansion in product range and functionality broadens the appeal of biodegradable tableware in everyday use scenarios.

Conclusion

In conclusion, the growing demand for biodegradable tableware in everyday use reflects a broader societal shift towards sustainability. Consumers are increasingly opting for products that minimize their environmental impact while still meeting their practical needs. As awareness grows and technological advancements continue, biodegradable tableware is poised to become a staple in households and businesses alike, contributing significantly to reducing plastic waste and promoting a more sustainable future.

0 notes

Text

Best Modular Kitchen Solutions In 2024

Source of info: https://www.linkedin.com/pulse/best-modular-kitchen-solutions-2024-regalo-kitchens-nlrxe

Introduction to Modular Kitchen

Modular kitchens are becoming more popular due to its ease, efficiency, and aesthetic appeal. As we approach 2024, demand for cutting-edge kitchen solutions grows, fueled by technological and design breakthroughs. Understanding the latest trends and advancements in smart kitchen design will help you make informed decisions while remodeling or creating a new home.

Consider building blocks for your kitchen. A smart kitchen is made out of prebuilt cabinets, drawers, shelves, and other pieces that can be mixed, matched, and organized to meet your exact space. This customisable method allows you to design a kitchen that suits your individual preferences and cooking style.

Why Choose a Modular Kitchen?

Here's why kitchen reign supreme in 2024:

Customization: Unlike traditional kitchens, modular kitchens provide enormous versatility. To construct a totally customized kitchen, you can choose cabinet sizes, layouts (L-shaped, parallel, U-shaped), materials, and finishes.

Space Optimization: Modular units come in a variety of sizes, making them perfect for tiny kitchens. They make good use of every inch of available space, even corners and strange niches.

Scalability: As your needs evolve, your kitchen can too! Modular kitchen allow you to add or remove units later, making them perfect for growing families.

Aesthetics: Gone are the days of dull kitchens. Modular alternatives are available in a wide selection of colors, textures, and finishes, from sleek and modern to warm and classic.

Cost-effective: Modular kitchens can be less expensive than custom-built ones. You simply pay for the units you need, and installation is usually faster.

Top Trends in Modular Kitchen for 2024

1. Smart Technology Integration:

The future is here! Modular kitchen is adopting smart technologies to improve the cooking experience. Consider voice controls for appliances, integrated lighting, and hidden charging stations.

2. Eco-Friendly Materials:

Sustainability is a prominent trend. Look for kitchens created with recycled materials such as bamboo or bioplastics. Additionally, energy-efficient equipment and LED lights add to an environmentally conscious kitchen.

3. The Rise of Multifunctionality:

Small kitchens necessitate clever solutions. Choose hidden pull-out drawers, corner units with rotating shelves, and cabinets that have integrated appliances such as microwave ovens or coffee makers.

4. A Touch of Luxury:

Include elegant finishes, such as high-gloss lacquer or metallic accents. Quartz counters are elegant, while integrated wine racks or display cases add elegance.

5. Personalized Touches:

Do not be hesitant to express yourself! A modular kitchen enables full personalization. To highlight your favorite kitchenware, consider using bright backsplashes, distinctive cabinet knobs, or open shelving.

Choosing the Right Modular Kitchen Solution

With so many options, here are some things to consider:

Space: Measure your kitchen precisely to decide the ideal plan (L-shaped, parallel, etc.).

Budget: Decide on a realistic budget and choose materials and features that fit your needs.

Storage: Analyze your storage requirements. Do you need a large pantry or utensil drawers?

Style: Browse design magazines or online resources to find a style that reflects your taste.

Functionality: Consider your food practices. Do you require a separate baking zone or a huge preparation area?

Conclusion: Building Your Dream Kitchen

Modular kitchen provides endless possibilities to design a kitchen that is both beautiful and useful. Understanding the newest trends, taking into account your demands, and selecting the proper features can help you make your kitchen into the center of your house in 2024 and beyond. Remember, don't be scared to explore and customize your area. After all, the ideal kitchen is one that reflects your individual style and makes cooking enjoyable!

1 note

·

View note

Text

5 Myths About Bioplastic Utensils Debunked

In the quest for more sustainable living, bioplastic utensils have emerged as an eco-friendly alternative to traditional plastic cutlery. However, like many innovative solutions, bioplastic utensils are surrounded by a range of myths and misconceptions. In this blog, we’ll debunk five common myths about bioplastic utensils and provide the facts you need to make informed choices. Contact us for more information or shop all of our products.

Myth 1: Bioplastic Utensils Are Just as Harmful as Regular Plastic

Debunked: One of the most pervasive myths is that bioplastic utensils are no better for the environment than conventional plastic. While it’s true that not all bioplastics are created equal, many bioplastic utensils are made from renewable resources like cornstarch, sugarcane, or potato starch. These materials have a significantly lower carbon footprint compared to petroleum-based plastics. Moreover, many bioplastics are designed to be compostable, meaning they can break down into natural elements without leaving harmful residues, unlike traditional plastics which can persist in the environment for hundreds of years.

Myth 2: Bioplastic Utensils Don’t Compost Properly

Debunked: Another misconception is that bioplastic utensils do not compost effectively and end up in landfills, just like regular plastic. The truth is, bioplastics require specific conditions to break down, such as industrial composting facilities where temperatures and humidity are controlled. While it’s true that these utensils won’t decompose as quickly in a backyard compost, in the right conditions, they can turn into compost within a few months, contributing to soil health rather than pollution.

Myth 3: Bioplastic Utensils Are Not Durable

Debunked: There’s a common belief that bioplastic utensils are flimsy and less durable than their traditional plastic counterparts. However, advancements in bioplastic technology have led to the production of utensils that are not only strong and sturdy but also heat-resistant and capable of handling various types of food. Many users find that high-quality bioplastic utensils can perform just as well as, if not better than, conventional plastic ones.

Myth 4: Bioplastic Utensils Are Too Expensive

Debunked: While it’s true that bioplastics were once more expensive due to limited production and higher material costs, the increasing demand for sustainable products has led to greater production efficiency and a reduction in costs. Today, the price difference between bioplastic and traditional plastic utensils is narrowing, making them a more accessible option for consumers and businesses alike. Additionally, the environmental benefits of choosing bioplastics can outweigh the slight cost difference, especially when considering the long-term impact on the planet.

Myth 5: Bioplastic Utensils Contribute to Deforestation

Debunked: Some critics argue that the production of bioplastics leads to deforestation, as large areas of land are used to grow the crops needed for bioplastic production. However, the reality is more nuanced. Many bioplastic manufacturers source their raw materials from sustainably managed farms that use crop rotation and other environmentally friendly practices. Additionally, research is ongoing to develop bioplastics from non-food sources, such as agricultural waste, which would further reduce the environmental impact.

Conclusion

Bioplastic utensils represent a promising step towards reducing our reliance on traditional plastics. By debunking these myths, we hope to provide clarity and encourage more people to consider bioplastics as a viable, sustainable option. At GreenTek Planet, we’re committed to offering eco-friendly products that help protect our environment. Choose bioplastics with confidence, knowing that you’re making a positive impact on our planet.

2 notes

·

View notes

Text

The Future of Sustainable Living: Trends in Compostable Biodegradable Products

As the global community becomes increasingly aware of the environmental impact of traditional plastics, the demand for sustainable alternatives is rising. Compostable biodegradable products are emerging as a key player in this green revolution. These innovative products, designed to break down naturally and enrich the soil, offer a promising solution to the mounting waste crisis. In this blog, we explore the latest trends in compostable biodegradable products and how they are shaping the future of sustainable living.

Understanding Compostable Biodegradable Products

Compostable biodegradable products are made from natural, renewable resources such as cornstarch, sugarcane, and bamboo. Unlike conventional plastics, which can take hundreds of years to decompose, these products break down within a few months under the right conditions. When composted, they not only disappear without a trace but also contribute valuable nutrients to the soil, supporting a healthier ecosystem.

Expansion Beyond Packaging

Initially, the focus of compostable biodegradable products was primarily on packaging, particularly in the food industry. However, the scope has significantly expanded. Today, we see these products in various forms, from cutlery and tableware to clothing, electronics, and even medical supplies. This diversification is driven by consumer demand and advancements in material science, making it possible to create durable and functional items that are also eco-friendly.

Integration in the Food Industry

The food industry is one of the largest adopters of compostable biodegradable products. Restaurants, cafes, and food delivery services are increasingly using compostable packaging and utensils. This shift not only helps reduce plastic waste but also caters to a growing demographic of eco-conscious consumers. Many establishments now brand themselves as sustainable by prominently featuring compostable products, thereby attracting more customers and setting a positive example.

Innovation in Materials

The development of new materials is a crucial trend in the compostable biodegradable products sector. Researchers and companies are constantly exploring plant-based materials that can replace traditional plastics. Innovations such as bioplastics made from algae and edible packaging derived from seaweed are on the horizon. These advancements promise to provide more versatile and sustainable options for a wide range of applications, from packaging to consumer goods.

Government Regulations and Support

Governments around the world are implementing stricter regulations on plastic use and offering incentives for using compostable biodegradable products. For instance, the European Union’s directive on single-use plastics bans many plastic items, encouraging the adoption of biodegradable alternatives. Such regulations are crucial in driving the market toward more sustainable practices and accelerating the transition to compostable products.

Increased Consumer Awareness and Demand

Consumer awareness about the environmental impact of their choices is at an all-time high. This awareness translates into increased demand for sustainable products. People are more inclined to purchase items that are labeled as compostable or biodegradable, even if they come at a higher price. This trend is pushing manufacturers to prioritize sustainability in their product development, ensuring that eco-friendly options are available across various product categories.

Improved Infrastructure for Composting

One of the challenges of compostable biodegradable products is the need for proper disposal methods. However, we are witnessing improvements in composting infrastructure. More municipalities are introducing composting facilities, and companies are providing home composting solutions. This enhanced infrastructure ensures that compostable products are disposed of correctly, maximizing their environmental benefits and encouraging wider adoption.

Corporate Responsibility and Sustainability Goals

Many corporations are setting ambitious sustainability goals, incorporating compostable biodegradable products into their operations. Companies like Unilever and Nestlé have pledged to make their packaging 100% recyclable, compostable, or biodegradable within the next decade. These commitments not only reduce environmental impact but also enhance brand reputation and meet consumer expectations. Corporate responsibility is driving significant changes in production and packaging practices across various industries.

Educational Campaigns and Certifications

Educational campaigns are essential in promoting the adoption of compostable biodegradable products. Certifications such as BPI and the Compostable logo by European Bioplastics help consumers identify genuinely compostable products. These certifications provide assurance about the product’s environmental benefits and encourage informed purchasing decisions, fostering trust and transparency in the marketplace.

Technological Advancements in Composting

Advancements in composting technology are making it easier and faster to break down biodegradable products. Innovations such as aerobic digesters and enhanced microbial treatments are improving the efficiency of composting processes. These technologies are crucial for managing the growing volume of compostable waste and ensuring that it decomposes effectively, returning valuable nutrients to the soil.

Conclusion: Embracing a Sustainable Future

The future of sustainable living lies in the widespread adoption of compostable biodegradable products. As trends indicate, there is a growing momentum towards eco-friendly alternatives across various sectors. By embracing these trends, we can significantly reduce our environmental footprint and move towards a more sustainable and circular economy. As consumers, businesses, and governments align their efforts, the vision of a world free from plastic pollution becomes increasingly attainable. Let’s embrace these innovations and make conscious choices that benefit both our planet and future generations.

In summary, compostable biodegradable products are not just a trend; they are a vital component of our journey towards a more sustainable future. By understanding and supporting these trends, we can collectively make a significant impact on the health of our planet.

0 notes

Text

Can Sustainable Dinnerware Be Composted

More and more people are choosing sustainable products to help protect the environment. One area where this is becoming popular is dinnerware. Many companies now offer plates, bowls, cups, and utensils made from natural or biodegradable materials. But can these products be composted? Let's break down this topic in an easy-to-understand way.

What Is Sustainable Dinnerware?

Sustainable dinnerware is made from materials that are better for the environment. Instead of plastic or Styrofoam, these items are often made from:

Bamboo

Palm leaves

Sugarcane fiber (also called bagasse)

Cornstarch-based bioplastics

Wheat straw

These materials break down more easily than traditional plastic and do not add harmful chemicals to the soil.

Composting Sustainable Dinnerware

Composting is a natural way to decompose organic materials and turn them into nutrient-rich soil. Many types of sustainable dinnerware claim to be compostable, but not all of them decompose in the same way. Essential factors to consider include:

Home Composting vs. Industrial Composting

Home composting: Some dinnerware, like those made from palm leaves or bamboo, can break down in a backyard compost pile. That said, the process can take several months or even longer.

Industrial composting: Some biodegradable plastics, such as cornstarch-based bioplastics, need high heat and special conditions to break down. These materials must go to a commercial composting facility.

How Long Does It Take?

Palm leaf plates: 6–8 weeks in a compost pile.

Bagasse (sugarcane fiber) products: 30–90 days in an industrial composting facility.

Bamboo utensils: Can take several months to over a year.

Bioplastics: Usually require industrial composting and may take 3–6 months.

What to Watch Out For

Check for coatings: Some plates and bowls have a thin plastic or wax coating to prevent leaks. These coatings may not be compostable.

Look for certifications: Labels such as “BPI Certified Compostable” mean the product meets composting standards.

Avoid misleading terms: “Biodegradable” does not always mean compostable. Some items break down very slowly or leave behind microplastics.

The Environmental Benefits

Composting sustainable dinnerware helps reduce waste in landfills and provides nutrients for the soil. Unlike plastic, which can take hundreds of years to break down, compostable dinnerware returns to nature much faster. Using these products can help create less pollution and support a healthier planet.

Conclusion

Sustainable dinnerware can be composted, but how and where it breaks down depends on the material. Some items can go in a home compost bin, while others need to be sent to an industrial composting facility. Always check labels and certifications to make sure the product is truly compostable. By choosing compostable dinnerware, we can reduce waste and take better care of the environment.

Frequently Asked Questions (FAQ)

Can I compost bamboo plates at home?

Yes, but they take a long time to break down. Cutting them into small pieces can help speed up the process.

What happens if I put compostable dinnerware in the trash?

If thrown in the trash, it will likely end up in a landfill, where it may not break down properly due to lack of oxygen and heat.

Are bioplastics really compostable?

Some are, but most require industrial composting. Look for official certification labels such as “BPI Certified Compostable.”

Can I compost paper plates?

Plain paper plates can be composted, but if they have a plastic coating or grease stains, they may not break down properly.

What is the best way to compost dinnerware?

If the item is home compostable, chop it into smaller pieces and mix it into your compost bin. If it requires industrial composting, check if your city has a composting facility that accepts it.

By making informed choices, we can all help reduce waste and protect the environment. Choosing compostable dinnerware is a small but important step toward a greener future!

0 notes

Text

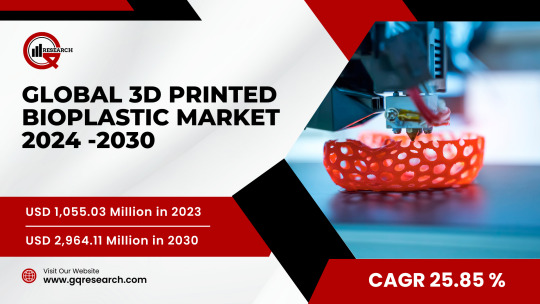

3D Printed Bioplastic Market: Growth Drivers, Emerging Trends and Future Outlook By 2024-2030 | GQ Research

The 3D Printed Bioplastic market is set to witness remarkable growth, as indicated by recent market analysis conducted by GQ Research. In 2023, the global 3D Printed Bioplastic market showcased a significant presence, boasting a valuation of USD 1,055.03 Million. This underscores the substantial demand for 3D Printed Bioplastic technology and its widespread adoption across various industries.

Get Sample of this Report at https://gqresearch.com/request-sample/global-3d-printed-bioplastic-market/

Projected Growth: Projections suggest that the 3D Printed Bioplastic market will continue its upward trajectory, with a projected value of USD 2,964.11 Million by 2030. This growth is expected to be driven by technological advancements, increasing consumer demand, and expanding application areas.

Compound Annual Growth Rate (CAGR): The forecast period anticipates a Compound Annual Growth Rate (CAGR) of 25.85%, reflecting a steady and robust growth rate for the 3D Printed Bioplastic market over the coming years.

Technology Adoption:

The adoption of 3D printed bioplastics marks a significant advancement in the field of sustainable manufacturing and biotechnology. Leveraging additive manufacturing techniques, 3D printing enables the fabrication of complex structures and customized products using renewable and biodegradable bioplastic materials. This technology finds diverse applications across industries such as healthcare, consumer goods, automotive, and packaging, where there is a growing demand for eco-friendly and customizable materials. From medical implants and prosthetics to biodegradable packaging and sustainable consumer products, 3D printed bioplastics offer innovative solutions to address environmental concerns and promote circular economy principles.

Application Diversity:

The application diversity of 3D printed bioplastics spans a wide range of industries and use cases, driven by their unique properties and environmental benefits. In the healthcare sector, 3D printed bioplastic implants and medical devices offer biocompatibility, flexibility, and customization options, enabling personalized treatments and improved patient outcomes. In the consumer goods industry, bioplastic materials are used to manufacture sustainable packaging, disposable utensils, and household products, reducing reliance on fossil fuels and minimizing plastic waste. Additionally, 3D printed bioplastics find applications in automotive components, architectural models, educational tools, and fashion accessories, showcasing their versatility and adaptability across different sectors.

Consumer Preferences:

Consumer preferences in the 3D printed bioplastics market are influenced by factors such as sustainability, performance, aesthetics, and cost-effectiveness. End-users increasingly prioritize environmentally friendly materials that minimize ecological impact and contribute to a circular economy. Bioplastics derived from renewable sources, such as plant-based polymers or biodegradable materials, resonate with environmentally conscious consumers seeking eco-friendly alternatives to traditional plastics. Furthermore, consumers value products that offer high-quality finishes, durability, and design flexibility, allowing for customized and personalized solutions that meet their specific needs and preferences.

Technological Advancements:

Technological advancements drive innovation and differentiation within the 3D printed bioplastics market, enabling manufacturers to develop materials with enhanced properties, processability, and performance. Ongoing research and development efforts focus on optimizing bioplastic formulations, additive manufacturing processes, and post-processing techniques to improve printability, mechanical strength, and surface finish. Advanced additives, such as reinforcing fibers, nanoparticles, and bio-based fillers, enhance the mechanical properties and functionality of bioplastic materials, making them suitable for a wider range of applications. Additionally, advancements in multi-material printing, digital design tools, and automation contribute to the scalability and efficiency of 3D printing operations, enabling mass customization and rapid prototyping capabilities.

Market Competition:

The 3D printed bioplastics market is characterized by intense competition among established players and emerging startups, driving continuous innovation and market expansion. Established material suppliers, as well as companies specializing in additive manufacturing equipment and services, compete for market share through the development of proprietary formulations, technology partnerships, and customer collaborations. Additionally, the market landscape is influenced by factors such as intellectual property rights, regulatory compliance, and industry standards, which impact the competitive positioning of companies across different regions and industry sectors.

Environmental Considerations:

Environmental considerations are central to the 3D printed bioplastics market, with a strong emphasis on sustainability, resource efficiency, and waste reduction. Bioplastics derived from renewable sources offer significant environmental benefits compared to conventional petroleum-based plastics, including reduced greenhouse gas emissions, decreased reliance on fossil fuels, and improved end-of-life disposal options. Furthermore, biodegradable and compostable bioplastic materials contribute to a circular economy by closing the loop on waste management and minimizing environmental pollution. Manufacturers strive to minimize the environmental footprint of 3D printing processes by optimizing energy consumption, reducing material waste, and implementing recycling and closed-loop systems. By embracing environmentally friendly practices and materials, stakeholders in the 3D printed bioplastics market contribute to a more sustainable and resilient manufacturing ecosystem, meeting the growing demand for eco-friendly alternatives and addressing global environmental challenges..

Regional Dynamics: Different regions may exhibit varying growth rates and adoption patterns influenced by factors such as consumer preferences, technological infrastructure and regulatory frameworks.

Key players in the industry include:

NatureWorks LLC

Arkema Inc.

BASF SE

Danimer Scientific

Evonik Industries AG

Fkur Kunststoff GmbH

Total Corbion PLA

Bio-On S.P.A.

API S.P.A.

Good Natured Products Inc.

The research report provides a comprehensive analysis of the 3D Printed Bioplastic market, offering insights into current trends, market dynamics and future prospects. It explores key factors driving growth, challenges faced by the industry, and potential opportunities for market players.

For more information and to access a complimentary sample report, visit Link to Sample Report: https://gqresearch.com/request-sample/global-3d-printed-bioplastic-market/

About GQ Research:

GQ Research is a company that is creating cutting edge, futuristic and informative reports in many different areas. Some of the most common areas where we generate reports are industry reports, country reports, company reports and everything in between.

Contact:

Jessica Joyal

+1 (614) 602 2897 | +919284395731 Website - https://gqresearch.com/

#3DBioplastics#SustainableManufacturing#RenewableMaterials#GreenTechnology#BioBasedPlastics#EcoFriendlyInnovation

0 notes

Text

Sustainable Solutions: Navigating the Compostable Foodservice Packaging Market

In recent years, the push for sustainability and environmental responsibility has prompted a shift in consumer preferences and industry practices, particularly within the foodservice packaging sector. This article explores the burgeoning for compostable foodservice packaging market, its role in reducing waste and environmental impact, and the factors driving its adoption.

Compostable foodservice packaging represents a sustainable alternative to traditional single-use packaging materials, such as plastics and styrofoam, which contribute significantly to environmental pollution and landfill waste. Compostable packaging is designed to break down naturally into organic matter when subjected to composting conditions, such as heat, moisture, and microbial activity, leaving behind no harmful residues or byproducts.

One of the primary drivers behind the adoption of compostable foodservice packaging is the growing awareness of plastic pollution and its detrimental effects on the environment, particularly marine ecosystems. Single-use plastics, including food containers, cups, utensils, and straws, contribute to the proliferation of plastic waste in oceans, rivers, and landfills, posing threats to wildlife, marine life, and human health. Compostable packaging offers a sustainable alternative that reduces reliance on fossil fuels, minimizes carbon emissions, and mitigates the environmental impact of plastic pollution.

Request the sample copy of report @ https://www.globalinsightservices.com/request-sample/GIS25647

Moreover, compostable foodservice packaging aligns with the principles of the circular economy, wherein materials are designed to be reused, recycled, or composted at the end of their lifecycle, rather than disposed of as waste. By diverting organic waste from landfills and incineration facilities, compostable packaging supports efforts to reduce greenhouse gas emissions, conserve natural resources, and promote soil health through composting, which enriches soil with organic matter and nutrients, improving its fertility and resilience.

The market for compostable foodservice packaging is driven by several factors, including consumer demand for sustainable products, regulatory initiatives to reduce plastic waste, and industry efforts to adopt eco-friendly packaging solutions. As consumers become increasingly aware of environmental issues and seek out products that align with their values, foodservice establishments are under pressure to offer sustainable packaging options that minimize their environmental footprint and appeal to eco-conscious customers.

Furthermore, government regulations and policies aimed at reducing plastic pollution and promoting sustainable packaging practices are driving the adoption of compostable foodservice packaging. Bans on single-use plastics, restrictions on plastic bags and straws, and incentives for composting infrastructure development incentivize businesses to transition to compostable alternatives and invest in sustainable packaging solutions that comply with regulatory requirements.

Additionally, industry collaborations, partnerships, and initiatives are driving innovation and investment in compostable packaging technologies, materials, and manufacturing processes. Packaging manufacturers, foodservice companies, waste management firms, and composting facilities are working together to develop compostable packaging solutions that meet the performance, durability, and safety standards required for foodservice applications while minimizing environmental impact and maximizing end-of-life options.

Despite the benefits and opportunities presented by compostable foodservice packaging, challenges remain in terms of cost, scalability, infrastructure, and consumer education. Compostable packaging materials, such as bioplastics and plant-based fibers, may be more expensive than conventional plastics, posing challenges for businesses seeking cost-effective solutions. Additionally, the availability of composting infrastructure varies by region, limiting the accessibility and feasibility of composting for some foodservice establishments.

Moreover, consumer education and awareness are essential for driving demand and adoption of compostable foodservice packaging, as misconceptions or lack of understanding about composting and recycling practices may hinder consumer acceptance and adoption. Clear labeling, educational campaigns, and public outreach efforts can help educate consumers about the benefits of compostable packaging and the importance of proper disposal and composting practices.

In conclusion, compostable foodservice packaging represents a sustainable solution to the environmental challenges posed by single-use plastics and conventional packaging materials. By promoting composting, reducing waste, and minimizing environmental impact, compostable packaging supports the transition to a more circular and sustainable economy, where resources are conserved, waste is minimized, and ecosystems are preserved for future generations. As consumer demand for sustainable products continues to grow and regulatory pressures mount, the market for compostable foodservice packaging is expected to expand, driving innovation, investment, and adoption of eco-friendly packaging solutions across the foodservice industry.

0 notes

Text

Crafting Excellence: The Art of Plastic Handle Manufacturing

In the vast landscape of consumer goods, there are elements often overlooked, yet integral to our daily lives. Consider the humble Plastic Handle. Found on everything from kitchen utensils to gardening tools, these unassuming components play a crucial role in our interactions with various products. Behind their simplicity lies a fascinating world of manufacturing intricacies and innovation. Today, we delve into this world to explore the craftsmanship and expertise that go into producing plastic handles, showcasing the journey from raw materials to finished products.

Understanding the Essence of Plastic Handles: Plastic handles serve diverse purposes, offering functionality, durability, and ergonomic designs. Whether it’s the comfort grip of a gardening tool or the sturdy handle of a suitcase, these components enhance user experience and convenience. However, crafting the perfect plastic handle requires more than just molding plastic; it demands a blend of engineering precision, material science, and design aesthetics.

The Role of Plastic Handle Manufacturers: At the heart of the process are plastic handle manufacturers, the unsung heroes of the industry. These companies specialize in transforming raw materials like polyethylene, polypropylene, or ABS plastic into a myriad of handle designs tailored to specific applications. From injection molding to extrusion techniques, manufacturers employ advanced methods to create handles that meet exacting standards of quality, strength, and usability.

Innovations Driving Excellence: In recent years, the landscape of plastic handle manufacturing has witnessed remarkable innovations aimed at enhancing both functionality and sustainability. Companies are increasingly exploring eco-friendly materials such as bioplastics derived from renewable sources, reducing the environmental footprint of their products. Additionally, advancements in 3D printing technology have opened up new possibilities for customizing handle designs with intricate textures and ergonomic contours, further elevating user comfort.

Quality Assurance and Compliance: Ensuring the reliability and safety of plastic handles is paramount for manufacturers. Rigorous quality control measures are implemented throughout the production process to detect any defects or irregularities. From material testing to stress analysis, every step is meticulously scrutinized to meet industry standards and regulatory requirements. By adhering to strict quality assurance protocols, manufacturers instill confidence in their products, earning the trust of consumers worldwide.

Collaboration and Customization: One of the hallmarks of the plastic handle manufacturing industry is its adaptability to diverse customer needs. Manufacturers work closely with clients to understand their unique specifications and preferences, offering tailored solutions that align with brand identity and market trends. Whether it’s a custom color palette, logo embossing, or ergonomic adjustments, collaboration between manufacturers and clients ensures that each handle is a perfect fit for its intended application.

The Global Impact of Plastic Handle Manufacturing: Beyond meeting local demand, plastic handle manufacturers play a crucial role in the global supply chain, serving industries ranging from household goods to automotive components. Their products find their way into homes, businesses, and industrial settings worldwide, contributing to the efficiency and convenience of everyday life. Moreover, as sustainability concerns continue to gain prominence, manufacturers are spearheading initiatives to minimize waste and promote recyclability, driving positive change across the industry.

Looking Ahead: Challenges and Opportunities: While the future of plastic handle manufacturing holds promise, it also presents challenges that demand innovative solutions. Rising environmental concerns and regulations necessitate a shift towards more sustainable practices, prompting manufacturers to explore alternative materials and recycling technologies. Additionally, the ongoing digital transformation is reshaping the landscape, with Industry 4.0 technologies offering new avenues for automation, efficiency, and product customization.

Conclusion: In the realm of consumer goods, plastic handles may seem like small components, but their impact is significant. From enhancing usability to driving innovation, these humble fixtures play a crucial role in our daily interactions with products. Behind every plastic handle lies a story of craftsmanship, expertise, and dedication, exemplifying the artistry of manufacturing. As we navigate the challenges and opportunities of the future, let us celebrate the ingenuity and resilience of plastic handle manufacturers, whose commitment to excellence continues to shape our world.

0 notes

Text

Impacts of Petroleum-Based Single-Use Plastics on Soil Fertility

Plastic pollutants is a vital ecological problem, and petroleum-based plastics used for single utilization create high risks of soil first-rate degradation. Each year, billions of tons of plastic go to landfills or come to be clutter. That being said, let’s understand why compostable plastic can be an ideal solution. Here’s an in-depth look at how different types of single-use plastics impact soil health and fertility:

Petroleum-Based Plastics

Traditional plastics derived from petroleum products inclusive of polyethylene and polypropylene were meant to be sturdy and industrious. This capacity to face up to decomposition lets in those plastics now not handiest to closing for decades but additionally centuries in the soil without degrading. Degrading plastic debris is also harmful as it releases toxic additives such as bisphenols and phthalates that are highly poisonous to beneficial soil microorganisms and earthworms. This is because these chemicals change the soil characteristics, such as composition and pH level, which makes it difficult for plants to absorb important elements from the soil. Avoid such materials by replacing them with compostable plastic items.

Oxo-Biodegradable Plastics

Some oxo-biodegradable plastic gadgets primarily based on petroleum can be bought as oxy or oxo-degradables, breaking down into smaller fragments whilst exposed to mild and air. Nevertheless, the microplastic fragments pile up in soil like common plastics. The little plastic fragments that carry additives and poisons pass into the tissues of plants as well as worms. The plastic stays in the soil for years.

Biodegradable Plastic Bags

Biodegradable plastic bags made of corn, sugarcane, or cellulose are claimed to be an eco-friendly alternative in evaluation with traditional plastics. Still, the bulk of municipal compost facilities do now not efficiently decompose such materials into secure compost. As a result, even biodegradable bags that become litter still contain microplastics after decay. The bags are only fully biodegradable under very specific conditions. Ultimately, as the fragments increase in soil they obstruct nutrient assimilation, water transport, and oxygenation of plants that largely depend on soils.

Biodegradable Plastic Utensils and Containers

PLA (polylactic acid) plastic isn’t biodegradable, which means that tableware and boxes made from it’s going to by no means degrade evidently. The soils do not function the desired microorganisms and environments for proper composting of these plastics. With the breakage of PLA containers and utensils into pieces, lactic acid is leached; this changes the pH in the soil and affects microorganisms’ activity. The fragments of microplastics may persist for years, negatively influencing the topsoil condition. Switching to biodegradable plastic bags is not just a need, but incredibly important in today’s time!

Preventing Plastic Pollution is Key

Even plastics marketed as biodegradable or compostable seem to be environmentally friendly alternatives, most of these forms of Single-use plastics need to be controlled fully so that plastic pollution will not damage the soil. Reusable and recyclable options must usually be decided on by way of clients. The producers have to reduce the plastic packaging and use materials which can be honestly compostable like paper, jute, and bamboo.

Governments should encourage renewable bioplastics and prohibit the most polluting choices. Startups can design unique biodegradable materials, which degrade under natural soils. By using a multi-faceted approach, we can prevent plastic waste from contaminating soils and preserve the planet’s agricultural destiny. If the soil is healthy, then it means that food production will be sufficient and appropriate to sustain life for many generations.

Improving the Soil Health in a Plastic-Contaminated Environment

If your garden soil has been contaminated with plastic pollution and chemical additives, there are steps you can take to rehabilitate the soil and restore fertility:

Remove Plastic Debris

Selectively collect any visible pieces of plastic litter and fragments from the first few inches of soil. Dispose of these properly. Sift the soil to separate smaller pieces of plastic and compost when possible. The first stage of plastic removal is physical debris.

Add Organic Compost

Apply several inches of quality compost into the top 6-12 inch depth. Organic compost increases the population of beneficial microbes that help in building a soil food web. It also has plant nutrients. Older compost is less contaminated.

Adjust pH Levels

If the test soil pH is acidic, add garden lime; if it’s too alkaline, apply sulfur. Plants do very well at a neutral pH of 6.5-7 most often than not Healthy pH ensures effective nutrient uptake by plants and increases microbial activity.

Plant Cover Crops

Plant nitrogen-fixing cover crops such as beans, peas, and alfalfa that feed on soil microbes. Their roots promote aeration and water retention. As cover crops outcompete weeds so there is no need to use chemical fertilizers.

In conclusion, biodegradable plastic bags are currently developing from sources that can completely degrade in composters used at home or in natural surroundings. These leave no toxic residue. With the refinement of formulas tailored for fast biodegradation in such diverse settings, researchers could be engaged in replacing single-use plastics entirely with rapidly degradable materials. Strict standards and testing will play an important role in ensuring that new materials are truly able to deliver on their environmental promises. Advancements continue and may eventually provide the convenience of plastic without impinging on soil health or ecological balance by using bioplastics. Nevertheless, minimizing the general usage of plastic is still crucial at this stage.

Source link

0 notes

Text

PLA Eco-friendly Bento Box with Utensils

This is considered eco-friendly since It’s made of bioplastic that’s from the polylactic acid of plant starches. This helpful bento box comes in one size (7.4″ x 5.1″ x 2.3″/18.8cm x 13cm x 5.8cm) that’ll be a great size for a delicious meal packed with flavor. On top of having utensils, you get a sturdy rubber band that keeps your food nice and safe. .: Material: 100% black PLA bioplastic .: One��

View On WordPress

0 notes